Youtube is a goldmine for tutorial videos but I found nothing on replacing the laser in the Denon 3910. I did find a video detailing replacement of a laser in a very similar model, close enough that I was able to do my 3910 and adapt to the slight differences. I've had the new laser in for a day now and it's playing both CDs and SACDs just fine. Got the NOS replacement for $17.00 from here:

https://www.ebay.com/itm/Denon-DVD3910-DVD-3910-Laser-Brand-new-Spare-Part-/122801607233?

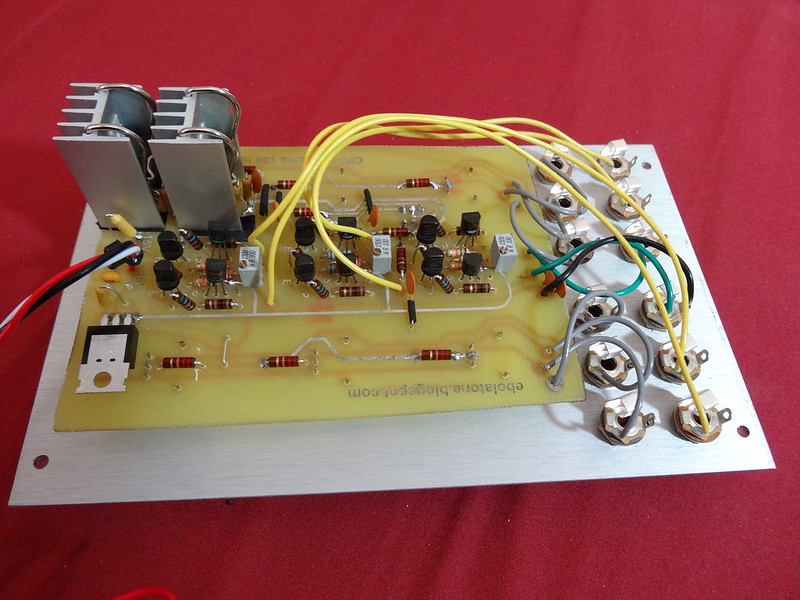

I only took a couple of basic photos to remind where certain screw types went so sorry, no documentation...after buying a Sony 9000ES in non-working condition for $1 and throwing hours and a new laser into it and it ending up not working well enough, I simply powered ahead and replaced it on the Denon and powered it up.

DO NOT ADJUST the Allen screws which adjust the height of the assembly/beam. That may be the one thing the gent in this video did wrong. There are three videos detailing his process but this first one should give you enough information to accomplish the replacement combined with my following notes.

Again, DO NOT ADJUST the Allen screws which adjust the height of the assembly/beam.

The 3910 has the same body as the unit in the video but a slightly different interior. The black front panel has to be unscrewed on top and bottom and pulled away a little and a metal bar across the top front held by two screws, removed to allow enough room to remove the covers on the laser assembly.

There is a ground wire between the front panel and the laser cover which slips under the front panel where a screw holds it in place; it also is screwed down to the top of the laser assembly so make note of where it went before removing.

Definitely plug it in momentarily and extend the tray; unplug with it extended. Instead of an internal plate covering the entire top of the unit per the one in the video, there is a small black plate with four small screws on top of the laser assembly which must be removed. Then the larger cover to the laser assembly as well. The ribbon connector can probably be removed first.

The ribbon connector has a tiny bar along the top where the ribbon inserts which must be pushed out a millimeter or two before removing the ribbon and of course pushed back when the ribbon is replaced.

Two flat head screws hold a small metal panel across the far end of the laser's travel. With it removed the two bars along which the laser rides are free, but note: there are as seen in the video two springs in the small black plastic piece upon which the two metal rods sit. Using a long screwdriver lift the two bars up (near the end so you don't remove or dirty the lubricant) from beneath and gently remove the black assembly with the two springs.

The defective laser can now be removed; the right bar and the white gears are attached so slide the laser off of the left bar so it's entirely free. Remove the white gear assembly and the metal bar.

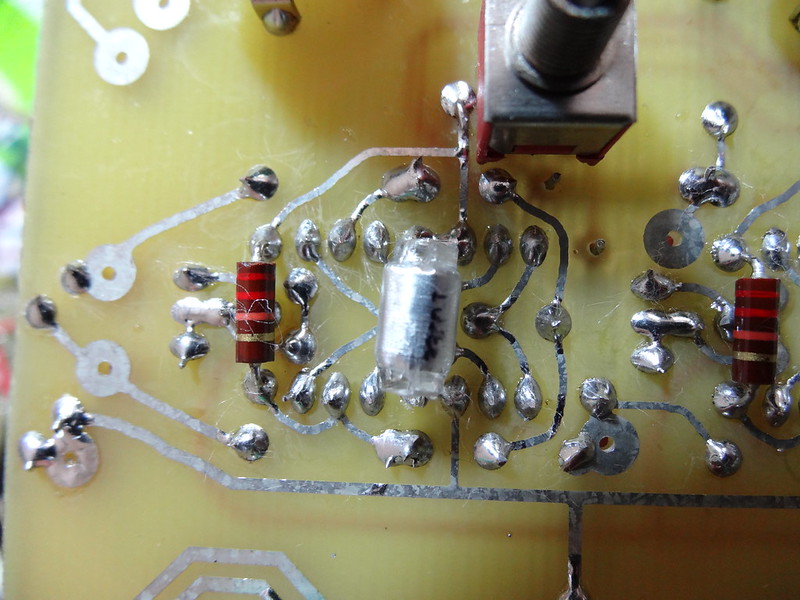

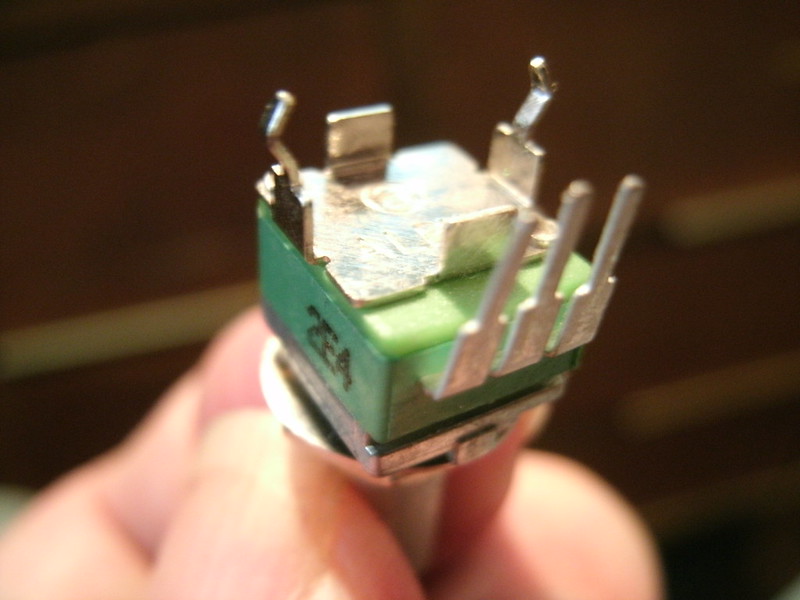

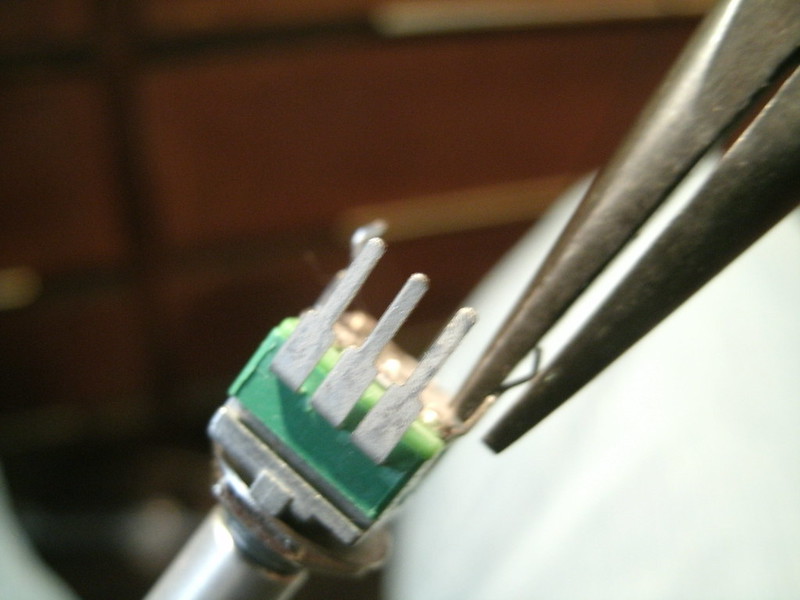

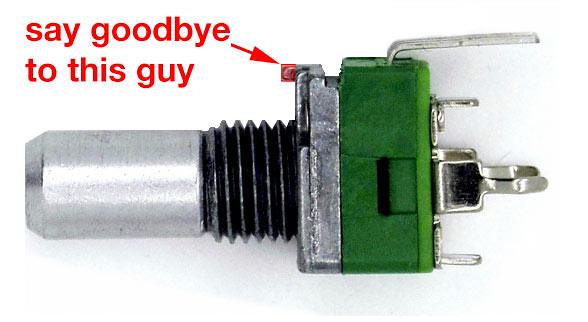

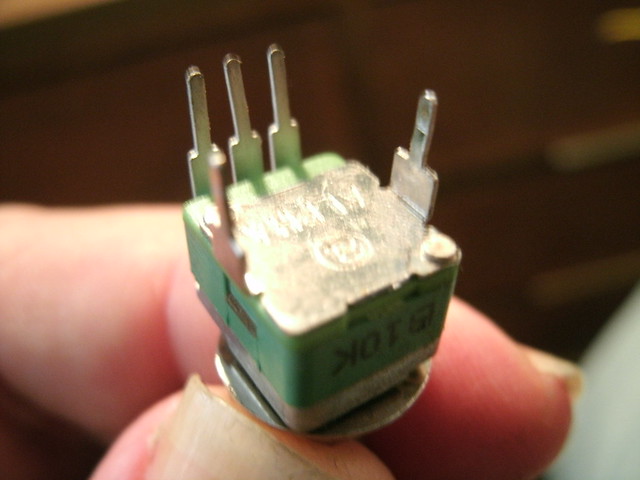

Ground yourself and unsolder the two anti-static solder blobs on the new laser mechanism (if unsure which two they are check the defective laser for reference). They're on plastic so don't melt the plastic in the process.

The left rod along which the laser slides can be left in place; the right comes out along with the laser to remove the white gear assembly. Slide the bar into the new laser assembly and attach the white gear assembly. You can now slide this onto the left bar still in place in the unit so both bars are now fitting to the front. Again lifting them, replace the black plastic piece with the two springs and rest the bars upon them. Replace the metal top and two screws. DO NOT ADJUST the two Allen screws in that assembly at any time.

Replace the ribbon and push down the clip. Replace the two laser covers making sure to remember the two wire holders on the left side and the small ground wire to the front panel on the right. You can replace the top metal bar across the entire front and its two screws now plus the front panel with or without again plugging it in to withdraw the disc tray. Don't forget the small ground wire from the laser which is screwed down between the frame and the front panel.

Plug in power and audio and give it a whirl! I encourage anyone who enjoys this player to not worry about trying this if they've previously done a laser replacement; it wasn't very difficult and requires no self-calibration afterward. Hope you're successful and that this helped!

https://www.ebay.com/itm/Denon-DVD3910-DVD-3910-Laser-Brand-new-Spare-Part-/122801607233?

I only took a couple of basic photos to remind where certain screw types went so sorry, no documentation...after buying a Sony 9000ES in non-working condition for $1 and throwing hours and a new laser into it and it ending up not working well enough, I simply powered ahead and replaced it on the Denon and powered it up.

DO NOT ADJUST the Allen screws which adjust the height of the assembly/beam. That may be the one thing the gent in this video did wrong. There are three videos detailing his process but this first one should give you enough information to accomplish the replacement combined with my following notes.

Again, DO NOT ADJUST the Allen screws which adjust the height of the assembly/beam.

The 3910 has the same body as the unit in the video but a slightly different interior. The black front panel has to be unscrewed on top and bottom and pulled away a little and a metal bar across the top front held by two screws, removed to allow enough room to remove the covers on the laser assembly.

There is a ground wire between the front panel and the laser cover which slips under the front panel where a screw holds it in place; it also is screwed down to the top of the laser assembly so make note of where it went before removing.

Definitely plug it in momentarily and extend the tray; unplug with it extended. Instead of an internal plate covering the entire top of the unit per the one in the video, there is a small black plate with four small screws on top of the laser assembly which must be removed. Then the larger cover to the laser assembly as well. The ribbon connector can probably be removed first.

The ribbon connector has a tiny bar along the top where the ribbon inserts which must be pushed out a millimeter or two before removing the ribbon and of course pushed back when the ribbon is replaced.

Two flat head screws hold a small metal panel across the far end of the laser's travel. With it removed the two bars along which the laser rides are free, but note: there are as seen in the video two springs in the small black plastic piece upon which the two metal rods sit. Using a long screwdriver lift the two bars up (near the end so you don't remove or dirty the lubricant) from beneath and gently remove the black assembly with the two springs.

The defective laser can now be removed; the right bar and the white gears are attached so slide the laser off of the left bar so it's entirely free. Remove the white gear assembly and the metal bar.

Ground yourself and unsolder the two anti-static solder blobs on the new laser mechanism (if unsure which two they are check the defective laser for reference). They're on plastic so don't melt the plastic in the process.

The left rod along which the laser slides can be left in place; the right comes out along with the laser to remove the white gear assembly. Slide the bar into the new laser assembly and attach the white gear assembly. You can now slide this onto the left bar still in place in the unit so both bars are now fitting to the front. Again lifting them, replace the black plastic piece with the two springs and rest the bars upon them. Replace the metal top and two screws. DO NOT ADJUST the two Allen screws in that assembly at any time.

Replace the ribbon and push down the clip. Replace the two laser covers making sure to remember the two wire holders on the left side and the small ground wire to the front panel on the right. You can replace the top metal bar across the entire front and its two screws now plus the front panel with or without again plugging it in to withdraw the disc tray. Don't forget the small ground wire from the laser which is screwed down between the frame and the front panel.

Plug in power and audio and give it a whirl! I encourage anyone who enjoys this player to not worry about trying this if they've previously done a laser replacement; it wasn't very difficult and requires no self-calibration afterward. Hope you're successful and that this helped!